Printed electronics features

Printed electronics offer many innovative features that open up new possibilities in a variety of fields:

Smart tags and packaging

The use of electronic display labels to replace price tags on supermarket shelves is a promising business opportunity. These electronic labels have a low pixel density and consume little energy. They not only provide information on a product’s price and characteristics, but can also alert sales staff when stock needs to be replenished on the shelf. They can be attached directly to the product to provide consumers with real-time technical (performance) and commercial information (discounts, etc.). This type of label is considerably more expensive than a traditional label, but offers the advantage of being reusable, as well as the possibility of centralized updating of information for all items in the store.

Increasing the added value of a simple cardboard box is now a priority for major brands. Analysts note that television advertising is losing its impact, while at the same time, consumers’ purchasing decisions are increasingly made in the store itself. Incorporating a flexible printed display into the packaging to provide information such as the list of ingredients, fat content or use-by date, can thus help to increase the perceived value of the product.

Another interesting market segment concerns so-called disposable electronics.

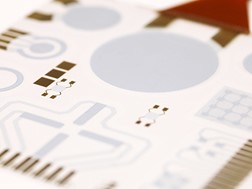

Professional multilayer ceramic capacitors

Made up of ceramic and metal layers, they feature complex shapes and advanced miniaturization. Mainly used in high value-added industrial sectors (aeronautics, aerospace, instrumentation, military, medical), they represent a $1 billion market.

Using traditional production technologies (strip casting, silk-screen printing, thermocompression), the introduction of direct ceramic and metal printing technologies reduces costs by a factor of two, while increasing performance by a factor of ten on half the capacitors in use today. With a French European leader in the manufacture of these components, France has taken a very serious lead in the application of direct printing technologies to the manufacture of ceramic multilayer capacitors, and should start production in the medium term.

©SUPRATEC JMD

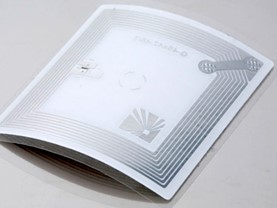

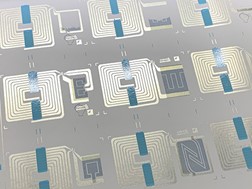

RFID antennas

The market for labels and other electronic identifiers will exceed €15B by 2022. It is currently growing at almost 15% a year.

However, this development is conditional on a significant drop in the price of these tags. At present, RFID tags are viable for pallet identification, but too expensive for individual packaging. The development of printed electronics is an interesting way of significantly reducing these costs, thanks to high-volume production techniques.

Printing is already widely used to produce RFID antennas, but the production of complete RFID tags using printing techniques alone is still in its infancy. To produce a fully printed complex circuit that meets the current performance standards achieved by silicon technology, a large substrate area would be required. It will take a few more years of research (including work on low-cost, high-performance conductive inks) before they can be truly competitive with traditional RFID tags. Today, the standard process requires a hybrid approach in which the Silicon chip is positioned at very high speed and bonded to the antenna using conductive adhesives (pick&place process).

In addition to the logistics sector, other applications are already being studied, such as freeway passes, loyalty cards equipped with RFID to send advertising, anti-counterfeiting marking, document marking to record and track files or works, security devices, passports, animal identification, etc.

Oleds

The technology is based on the use of organic superimposed diodes which, once powered by an electric current, emit their own light by combining a charge-hole pair emitting a photon, unlike other types of display such as liquid crystal displays, which require backlighting on a network of optical valves.

Oleds for lighting

Energy-intensive lighting technologies (incandescent, halogen) are gradually being replaced by new ambient lighting created directly on walls, ceilings, curtains, windows or any other surface capable of integrating organic LEDs. These technologies are increasingly being integrated into automotive safety lighting systems (rear lights on certain luxury cars, for example, enabling innovative and unique designs).

Oleds for screens and displays

OLEDs have already largely conquered the display market for all small mobile devices. They have now moved on to tablets, high-end cell phones and computer screens, for reasons of image quality, contrast and color gamut compared with LCD. They are compatible with flexible substrates, but remain difficult to produce due to the need for high-performance encapsulation systems.

©CEA-Liten

©FEDRIGONI

Batteries

They are structurally thin and flexible, can have widely varying form factors, and can be integrated into disposable objects, but they still cost more than most conventional button cells, so their use is still limited to niche applications such as medical patches, where their flat, extremely compact appearance is an essential factor.

Printed batteries (rechargeable cells) are now available on the market and can be used to power most printed applications. The manufacturing process is screen printing. The electrical voltage reaches 1.5 V in normal operation, enabling power to be supplied to the Internet of Things (IoT). New players are now introducing solutions based on materials derived from green chemistry, making the problem of recyclability of smart objects containing embedded electronics easier to solve.

Sensors

Unlike segments such as flat-panel displays or RFID, there are still relatively few players in this field, given the development prospects offered in areas such as security and healthcare (diagnostics and therapeutic applications).

Promising outlets for sensors printed on flexible substrates are emerging in the construction, protective clothing, military uniforms, packaging, robotics, aerospace and energy sectors. The ability to prepare them in highly variable form factors and surfaces opens up numerous applications that would be inaccessible with Silicon or inorganic equivalents (quartz, etc.). The main technological hurdle lies in the availability on the market of inks suitable for the production of these various devices, i.e. inks with sufficient sensitivity to detect particular substances or environmental conditions.

©ARKEMA

©FEDRIGONI

Intelligent systems

Combining multiple functionalities to perform complex tasks autonomously is a response to the growing development of connected objects. What’s new is the use of flexible substrates to build complete systems that integrate measurement, logic and energy functions.

Organic electronics enable the integration of several functions on a single substrate, and the design of integrated systems or intelligent sensors. These “systems on foil” take the form of flexible intelligent sensors that are inserted into textiles or bonded to surfaces, for applications involving monitoring of the external environment (temperature, pressure, etc.) or health, and compatible with label formats.

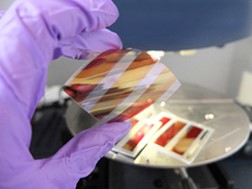

Photovoltaics

Organic Photovoltaics (OPV) consists of depositing layers of organic inks on a flexible plastic film, to create customized, environmentally-friendly, energy-producing photovoltaic modules. These flexible modules can be used in an infinite number of applications, making even the most complex objects self-sufficient in energy, even under artificial sunlight. The range of available colors makes the modules compatible with product design and aesthetics. Compared with silicon modules, they are flexible, lightweight and semi-transparent. However, due to the nature of the materials used, their quantum efficiency is lower than that of silicon diodes, and they have a shorter lifespan, requiring excellent encapsulation.

The thin-film photovoltaic market offers clear advantages over conventional crystalline silicon-based photovoltaics: lower cost and weight, flexibility and simpler integration on buildings or lightweight structures (on agricultural greenhouses, for example, in the case of agrivoltaics).

Production can be carried out on a Roll-to-Roll basis, enabling cost structures compatible with mass markets.

©ARMOR Group